Corncobs into power: a Uganda case study + new ROI calculator

Making energy From “waste”– a case study in corn from Uganda As part of Richard Scott’s recent African field trip, he stopped in to help Pamoja Cleantech set up their new Power Pallets in Kampala, Uganda. This project–as well as the previous one discussed in Liberia, and the one we’ll report on soon from Malawi– are all proof of concept projects for a larger roll out of rural electrification in Africa using biomass gasification. Pamoja Cleantech’s gasifiers (Pamoja means “together as one” in Swahili) are running on corn cobs, with the energy being used to power a corn flour mill……

Case study: Liberia-making energy from scratch + videos

Power Pallet Case Study: Liberia In recent months there’s been a noticable spike in the interest in our Power Pallets, especially from places where energy is either very expensive, or […]

Grid-tie for the 20kW Power Pallet

We’ve long wanted to provide a reasonably priced grid-tie solution for the Power Pallet. However sync equipment for small scale systems is scarce, and usually at price points near equal the Power Pallet itself. Today we’re announcing the availability of a fully complete, non-hacked, and equipment certified grid-tie solution for the 20kw Power Pallet for $4,995. This is a solution that will work for nearly all global grid standards, as well as enable off-grid parallel feeding with large gensets already at your facility. We think this tie solution is a game changer for the broad usability of the Power Pallet.……

APL in the Field: Powertainer install at UNM Morris

Bear Kaufmann, Jeff Tiedeken and Jim Mason are at University of Minnesota, Morris this week installing the Powertainer and setting it up for its initial runs onsite. This has been a long haul, and we’re very happy to finally have it here and soon begin pumping biomass power back into the grid. A big thank you goes to Lowell Rasmussen, Jim Barbour and Dave Aronson at the UMM for making this project possible, as well as their general dedication to proving small scale biomass energy for midwestern ag applications. As well a huge thank you to APL team member Nick Monahan……

APL in the Field: Indonesia Report

Yoav and I just returned from a trip to Indonesia to help with the set up and operational instruction for 2 Power Pallets there. They are being integrated into a pilot stage “Village Hub” project. This pilot is located next to a palm sugar factory run by the Masarang Foundation (http://www.masarang.nl/). The factory uses waste geothermal heat from a 35 MW geothermal plant to dry and prepare palm sugar. This sugar is prepared from the sap of the Arenga Palm (http://en.wikipedia.org/wiki/Arenga_pinnata), a species studied by Willie Smits who studied forestry in the Netherlands (and gave a great TED talk. The……

Village Hub, Suliwesi, Indonesia – April 2012

The Masarang Foundation Integrated a PP10 Power Pallet into their sustainable Village Hub system for palm sugar harvesting on the Island of Suliwesi in Indonesia. This pilot project is located next to a palm sugar factory which uses waste geothermal heat from a 35 MW geothermal plant to dry and prepare palm sugar. This sugar is prepared from the sap of the Arenga Palm which can be processed into sugar and ethanol. The Arenga palm can grow on poor soils, allowing deforested areas to be reforested, acting as a nurse tree to re-introduce more diverse species. The Village Hub concept is to……

Gasification Workshop Weekend: March 30 – April 1, 2012 Berkeley, CA

Gasification PowerExchange Workshop #11: March 30 – April 1 2012 Gasifier Power System Showcase: 10kw, 20kw & 100kw, GEK building and running, More Lister spark conversion Gasification Lecture and Demo: Friday, March 30, 7:30-9:30PM Building, Running and and Testing: Saturday and Sunday, March 30 and April 1, 11am – 7pm Location: ALL Power Labs, 1010 Murray Street. Berkeley, CA Contact: sales ^at^ allpowerlabs.org Cost: Free for GEK owners. $100 otherwise Join us at ALL Power Labs in Berkeley CA, March 30 – April 1 for the next in our long running series of Biomass Gasification workshop weekends. It has been way too……

GEK v4.2 Gasifier Fabrication Guide – Build Your Own!

Welcome back after a quiet late summer sans Geknews posts. Sadly, quiet on this end didn’t relate to the long planned trip down Baja. Rather, we’ve been face down in the details of scaling our 10kw and 20kw Power Pallet production, as well as sprinting towards the finish of our first 100kw shipping container based system. This of course is not a problem, and we thank all of you for making this adventure more interesting with each passing month. The challenge now is just keeping up with the growth in interest and all of your notes. We’re now 15 people full time at……

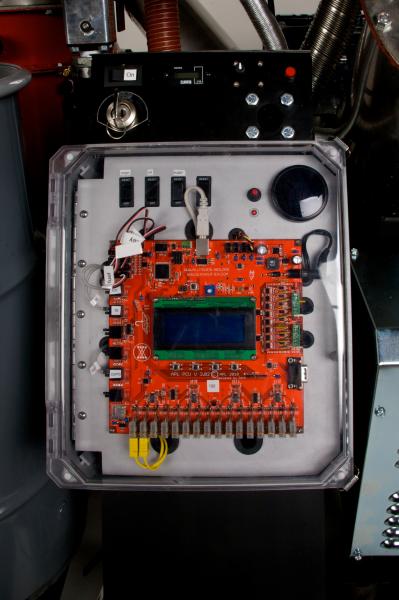

A Closer Look At The 2011 Power Pallet

The first edition of the 10kW GEK Power Pallet combined our Tower of Total Thermal Integration with a Kohler v-twin engine. In October of 2010 we began production of the second version, which used a Kubota 3-cylinder industrial spark-fired diesel designed specifically for use with a gaseous fuel, and a Meccalte genhead that could be configured to the requirements of the user’s energy network. This engine, when governed electronically, is stunningly smooth and quiet. Here is a feature-by-feature breakdown of the innovations that have been incorporated into the current Power Pallet line: Control Panel Mount The Process Control Unit and……

Next Workshop Weekend: June 17-19. Update on BEK production

*** FATHER’S DAY GASIFY WITH DAD WORKSHOP *** Join us at ALL Power Labs June 17th through 19th for our next Gasification and Biochar Workshop in Berkeley CA. This is Father’s Day weekend so we hope you will consider planning a father-and-son/daughter trip to All Power Labs for our workshop. It has been too long since our last workshop. Our first quarter 2011 workshop in the Ivory Coast was canceled due to political unrest. Then we found ourselves too busy building in-house to have one in the spring. So we’re now giving you lots of notice for our summer workshop. ……