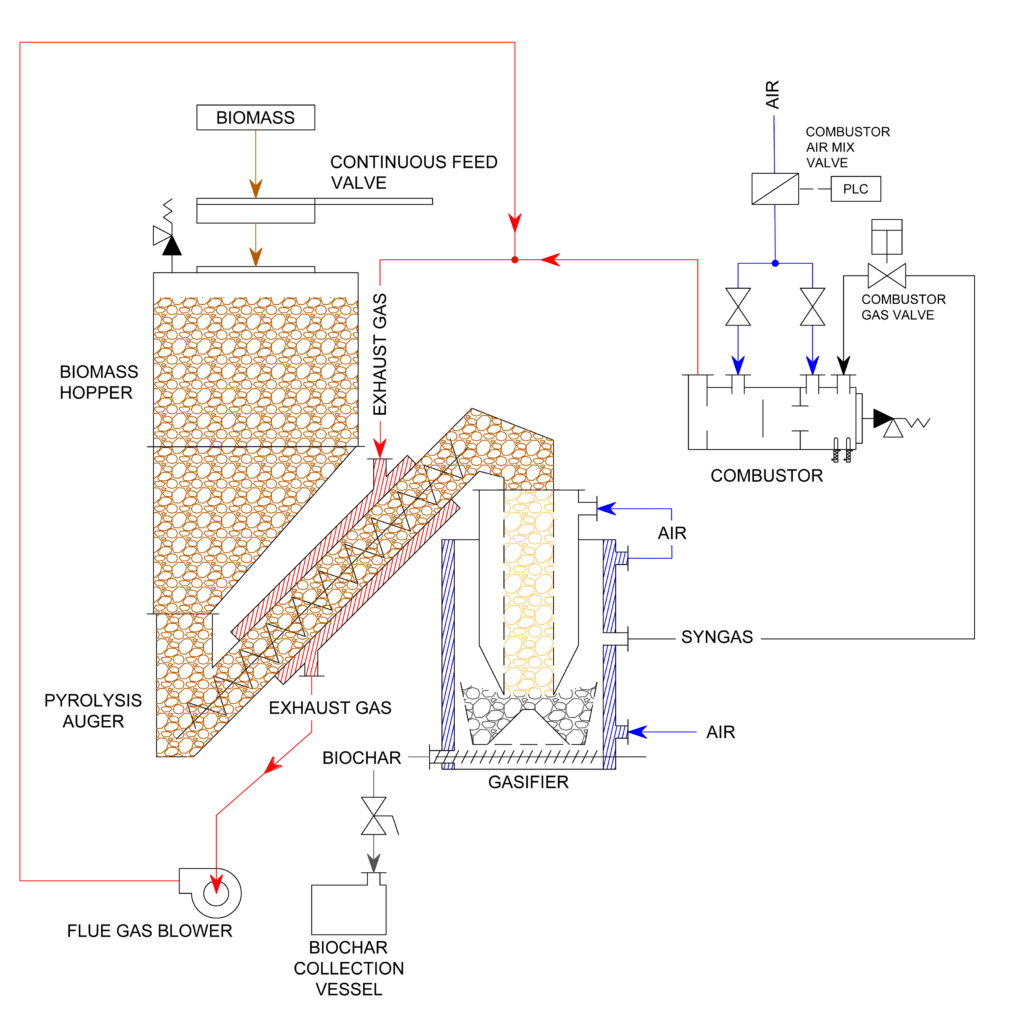

The ALL Power Labs CharPallet 25 (CP25) integrates extensive innovations into our third-generation smart, compact, and versatile v3.0 biomass gasifier system which can convert up to 25 kg/hr of waste biomass into biochar, syngas, and heat. These developments are in response to increasing demands for reliable biomass processing for the biomass/biofuel research sector, efficient biomass waste disposal, and high-quality biochar for the agronomy and climate/carbon mitigation sectors.

Improved Gasification Process:

Excellent Carbon and Gas Outputs – Extensive testing and process refinement for more than a decade results in high-quality product outputs:

Smart Technology – Smarter than any previous APL products, the CharPallet uses Internet of Things (IoT) protocols and systems that include:

Modular Design – The v3.0 biomass gasification system is configurable to support the following use cases:

We are planning for pre-sales of the CharPallet to support limited production release in late 2025 with target base price well below our Power Pallet.

We will be able to meet this target by getting a minimum number of reservations to enable negotiations with our suppliers. Reservation fee is $300 per unit and adds you to the production queue.

Click for CharPallet reservation here.

Please fill out this Contact Form along with details of your use case so we can respond appropriately.

The Pilot version of the CharPallet will be available to a limited number of customers starting in late 2025. We expect to have units available to retail customers in 2026.

We expect the price of a base system to be substantially less than our Power Pallet. We also plan to offer a more fully featured and instrumented research version for about a $10,000 premium. Our supply chains are currently extremely volatile, please contact sales@allpowerlabs.com for our most current pricing.

The CharPallet is an excellent tool for academic institutions working in R&D or education in the biochar and renewable energy spaces.

• Users with biomass waste streams can use the equipment for on-site disposal to minimize waste disposal logistics and costs.

• Small agricultural producers and gardeners can turn their woody waste into a value-added product that can be sold, traded, or used as a key ingredient in restorative soil amendments, minimizing their carbon footprints while adding reputational value to their products.

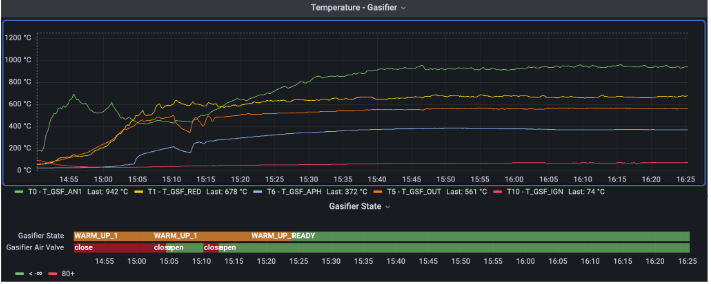

Please review this Appropriate Feedstock link. However, ongoing testing and refinement of our novel tar-cracking Swirl Hearth reactor architecture indicates greatly expanded compatibility with a wider range of feedstocks. So far we have confirmed its ability to handle much finer biomass particles than our previous reactors: ~1/8in (~3mm).

The quality of the biochar produced is highly conductive with extremely low tar/PAH content. Please review these Skycarbon Specifications which show biochar qualities and certifications for walnut feedstock. We have been recording similar results with for other feedstocks.

The emissions are kept very low through a sophisticated cyclonic combustor with real-time NOx feedback for mixture optimization. Third-party emissions testing to EPA standards is in process. We will continue to share results with potential customers.

The CharPallet is planned to be a Combined Heat and Biochar (CHAB) production reactor with a biochar output of 5kg/hr compared to the PP30’s 2kg/hr. It can be configured to provide 50kWth heat output, similar to the PP30 but consuming 2kW of electrical power rather than any electrical output. It is roughly half the footprint and price, and one quarter the weight of the PP30.

No. The syngas produced is consumed in a low-emission, high-efficiency combustor whose heat energy can be output via an optional hydronic heat exchanger.