Many factors are involved in the successful operations of a Power Pallet. Please review the following considerations that should be taken into account for each specific use case.

Feedstock Requirements

The PP30 requires feedstock consisting of pieces larger than ½ inch, but smaller than 1 ½ inches. (Larger than 1 cm, smaller than 4cm.) The moisture level of the feedstock must be under 30%; best performance is obtained with moisture content less than 25%.

Feedstock Processing and Handling

Chipping

The most commonly used feedstock with the PP30 is wood chips. If you intend to use wood chips with the PP30, you will need a wood chipper. The acceptable chip size range is 1 cm to 4 cm. The two popular options are auger chippers and disc chippers. Auger chippers (such as the Laimet brand from Finland) use one auger per chip size. These chippers produce very consistent chips, but are significantly more expensive than disc chippers. Disc chippers are much more common, but their chips must be sifted to isolate the correct sized chips, resulting in some loss from the fraction of the feedstock excluded by sifting.

Sifting

The PP30 ships with several screens for manually sifting feedstock. For cost-effective preparation of large quantities of feedstock, we recommend preparing a mechanized sifter.

Restrictions

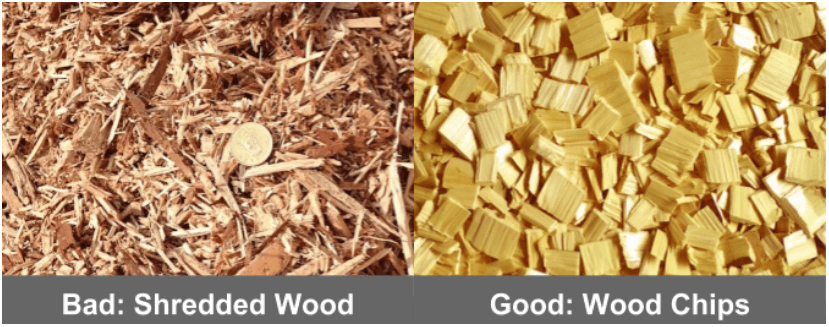

Currently, the only approved feedstocks wood chips, coconut shells, tree nut shells (except for Almond husks and cashew husks), and corn cobs (with increased maintenance). Note: do not confuse wood chips with wood shavings or shredded wood. Shavings and shreds are not suitable because of constant feedstock jams. The following examples contrast chipped wood from shredded wood:

Loads

Minimum and Maximum loads

An individual PP30 has a minimum required load of 3kW, and a maximum rated output of 25kW. Under the minimum required load of 3kW, the reactor will not be hot enough to produce clean gas. Rapid fouling of the gas filter and throttle may result from running the machine at low loads. If you require a load capacity higher than the rated power output, it is possible to synchronize several GridTie model PP30s to form a microgrid.

PP30 microgrids for scaling to load

The PP30 can be synchronized with other AC power sources to form a microgrid using the integrated gridtie electronics that come standard on the machine. Multiple PP30s can be synchronized to form a microgrid that can support loads in excess of the rated capacity of a single PP30. The PP30 is well suited for systems that are intended to supplement small scale wind turbines or solar panels.

Operational sessions

The PP30 is not designed to operate continuously for days at a time; it is designed to have operation sessions punctuated by required maintenance cycles when the vessel that collects the char-ash (usable as biochar) and soot from the cyclone filter need to be emptied. The session time can be as long as 12 hours at maximum load. Lesser loads may enable longer session times.

Waste heat recovery

The PP30 has an integrated Combined Heat and Power (CHP) module for recovering waste heat from the radiator coolant fluid and the gas produced by the gasifier, as well as an option to recover heat from the exhaust of the engine. The CHP module produces heat roughly in proportion to the load on the engine, and can provide up to 50kW of thermal energy in the form of hot water. See the data sheet for the CHP module for more details.

Facilities Recommendations

When budgeting for the purchase of a PP30, be sure to factor in the cost of preparing the facility for it. The facility must:

● Protect the PP30 from rain and direct sun exposure

● Have a fireproof hood over the flare

● Have good ventilation

Accommodating the Flare and Exhaust

The PP30 has a flare that is used to burn off the smokey gas produced while the reactor is warming up. The facility must have a fireproof hood that can vent the flare gases, and sufficient ventilation to protect the machine operator from exhaust and from any gases released during maintenance operations.

Feedstock Processing, Storage, and Refilling

We recommend that the feedstock chipping, drying, and storing equipment and structures be built together with the facility that houses the PP30. For refilling your PP30’s hopper, we also recommend building a mezzanine just tall 4 of 9 enough to facilitate the refilling process. Otherwise, refilling will involve having a worker climb a ladder multiple times with a bucket to refill the hopper.

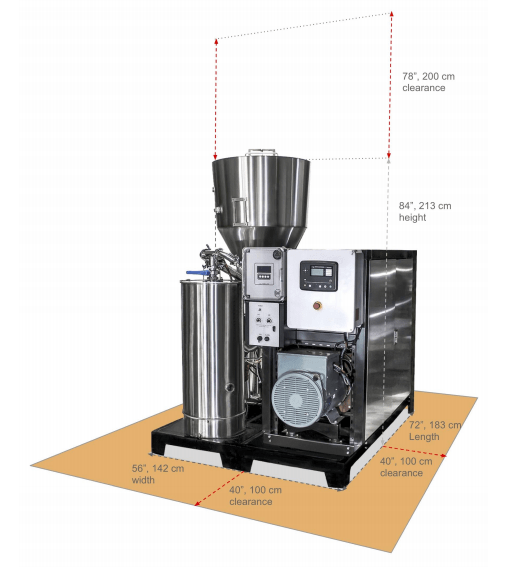

Minimum Clearance Requirements

The PP30 requires at least 1 meter of clearance on all sides, and at least 1.75 to 2 meters overhead.

Maintenance

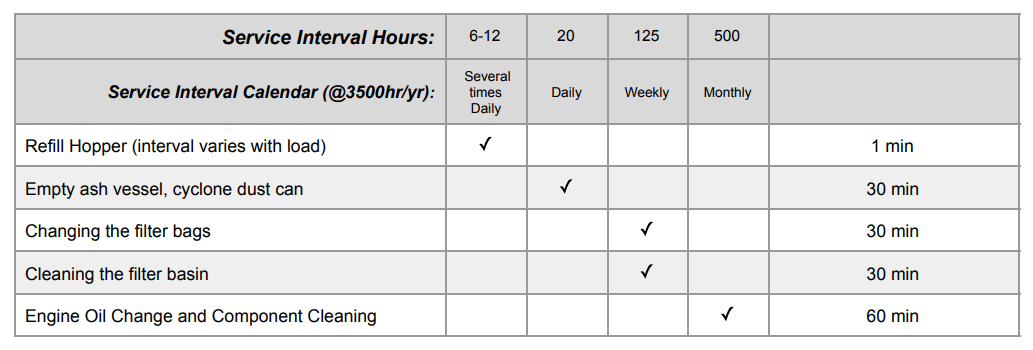

Daily maintenance involves

- Refilling the hopper when it is ¼ full

- Emptying out the charash and cyclone dust cans after shutdown.

Other maintenance tasks on the regular schedule:

- Changing the filter bags

- Cleaning out the soot and dust in the filter basin

- Changing the engine oil

- Other maintenance tasks are indicated on the maintenance schedule shown below:

Electrical Distribution and Load Balancing

You will need some way of distributing the electricity generated by the PP30. We recommend obtaining a distribution box or having your electrician plan the circuitry for distributing the electricity. See the list of supported electrical configurations for details about electrical configuration options.

Shipping Costs

Our proforma price quotes do not include the cost of shipping because it changes weekly, but the lead time for the PP30 is 120 days. Any shipping price quoted would only be valid for 30 days at most. To obtain a shipping estimate, please provide the name of the nearest port or airport that can receive cargo. We ship according Incoterms Ex Works rules (EXW).

Biochar

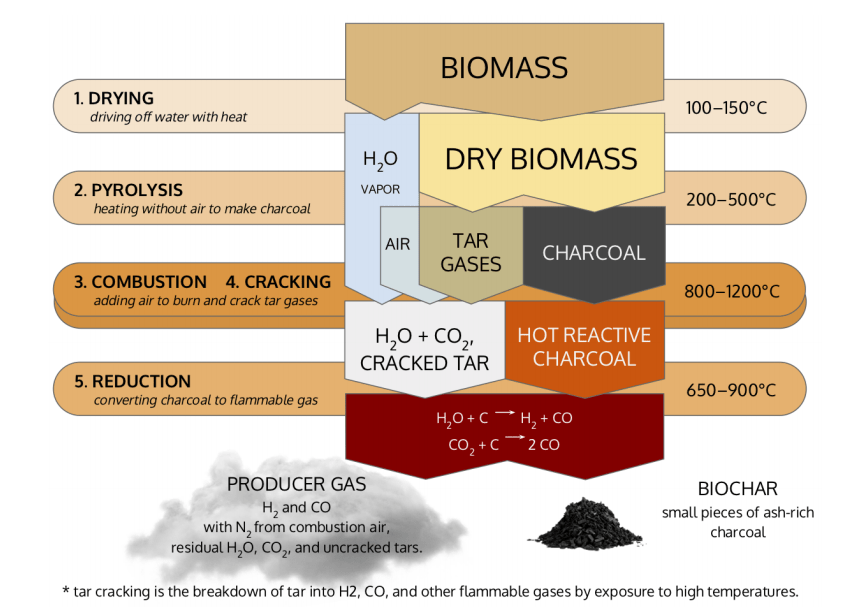

Biochar is charcoal used as a soil amendment. The Power Pallet PP30 produces small pieces of charcoal as a byproduct of its gasification process.

The biomass is turned into charcoal during the pyrolysis stage; during the combustion and cracking stage, a portion of the tar gases are combusted in the void spaces between the pieces of char, while the high temperatures crack the remaining portion into light gases. This high temperature exposure turns the char conductive, a quality which confers many benefits in the compost heap and in the soil. The combustion products then percolate through the char in the reduction stage, where a portion of the char is consumed to produce gas. As the reduction reactions occur, the char pieces shrink, and eventually get shaken out of the basket in the reactor that holds all of the char. These pieces of char are what constitute the biochar output of the gasifier.

The resulting biochar has the following notable qualities:

- It has high electrical conductivity due to having passed through a high temperature process. Conductivity is a beneficial quality, as it significantly facilitates the exchange of electrons among soil microbes

- It has very high porosity and surface area

- It is very hydrophilic, and has an excellent water holding capacity

- It has very low tar levels; the tar cracking breaks down much of the tar, while a constant flow of gas through the hot char takes any residual tar gases away from the char while it is at temperatures too hot for tar to condense on it.

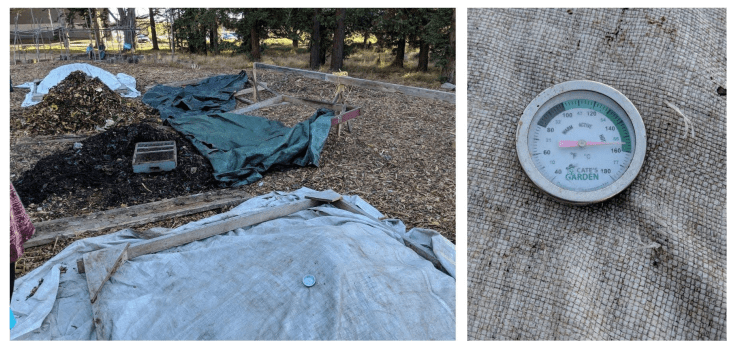

How to use gasifier biochar

The biochar should first be watered until it is soaking wet. The wet char should then be mixed with compostable materials at about a 1:10 ratio for hot aerobic composting. The compost should be turned twice a week for the first two weeks, and then weekly until it is mature. The full process may take two months.

Benefits to Compost

- Hotter, more thorough composting

- Reduced odors

- Harmful emissions (methane, N2O) reduced

- Nutrient loss reduced, captured on char

Benefits to Soil and Plants

● Cocomposted biochar increases the soil’s water holding capacity

● Soil texture is improved: water permeability, porosity, and moisture wicking are all significantly improved.

● The population and activity of growth promoting rhizobacteria is increased.

● Soil fungal population and activity are increased; soil fungi mediate the availability of phosphorus.

● Freeliving nitrogenfixing bacterial populations and activity are increased, reducing need for fertilizer.

● Fertilizer utilization efficiency is increased; if fertilizer is still needed, much less is needed.

In summary: Expect rapid and vigorous plant growth with no added fertilizer in the first growing season, and minimal inputs thereafter. Expect reduced need for water.

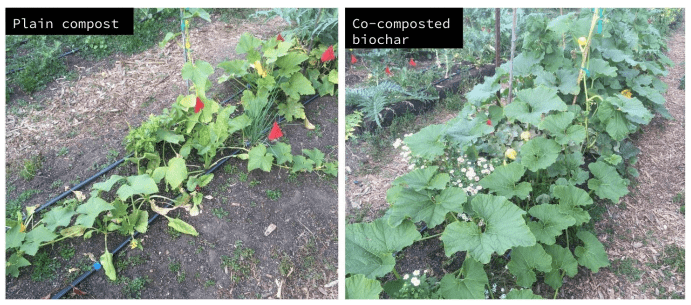

Examples of results from cocomposted biochar

Artichoke

In the example above, it appears that plant pathogens survived the composting process for the compost used on the artichoke on the left, whereas the biochar compost used on the artichoke on the right was free of pathogens.

Pumpkin

This pair of pumpkin plants showed an absolutely astounding difference in the rate of growth. In spite of being planted at the same time, the one that received the biochar compost exhibited a rate of growth and a level of vigor that utterly dwarfed the one that merely received compost.

Broccoli

The broccoli plant that received plain compost is not unhealthy nor deprived by any measure, but its growth is completely dwarfed by the broccoli that received cocomposted biochar.