GEK – $18,995

PP20 – $26,995

PT 150 – Available 2017

Updated Classic: GEK Gasifier Kit

ALL Power Labs began in 2008 by selling small-scale gasifier kits for DIY enthusiasts and university researchers. Our intent was to provide a LEGO kit of gasification to spark new work and new conversation in the relatively uneventful field of biomass thermal conversion. Over the following years we were amazed at the interest these kits generated globally, and the acceleration of collaborative research and knowledge exchange that followed.We ultimately found that a gasifier based power generation system–one that actually delivers on its value proposition–requires an integration of components and high level automation that a raw DIY kit cannot provide. Thus for years we have said no to the continuing requests for these kits, and instead directed people to our full power generation systems.This did not stop the requests, nor the desire/belief of many people that they can build out the system themselves. So after years of resistance, we’ve figured out a new scenario for offering a more basic gasifier kit based on our dramatically improved v5 gasifier, but still with a level of integration and automation that keeps it meaningful for actual use.

In May 2015 we introduced the new form of the GEK Gasifier Kit (warning: it might look somewhat familiar):

The Full Solution: PP20 Power Pallet

The Power Pallet is a complete biomass power generation solution that converts dense biomass like wood chips and nut shells into electricity and heat. It is a compact, integrated system – from biomass in, to power out – delivered at the newly reduced price under $1.40/watt.

The Power Pallet is comprised of the GEK Hot TOTTI multi-stage gasifier, spark fired industrial engine, generator head, and electronic controller. The system automatically adjusts syngas/air mixture via a wide band Bosch oxygen sensor, shakes the grate when needed, and removes ash via a mechanical auger. The Process Control Unit (PCU) monitors and responds to all internal reactor, filter and engine conditions, displaying the results on an LCD screen.

Power Pallet genheads are configurable to single, split or three phase, at 120/208/240Vac, 60hz or 50hz. We also offer an optional grid-tie package.

Optional Accessory: Continuous Feed Airlock

To eliminate manual refilling of the hopper, ALL Power Labs is now offering a Continuous Feed Airlock as an option on all Power Pallets. Controlled by an Electronic Control Unit (ECU) with an array of sensors, this system allows a store of feedstock at ground level to be automatically fed, via a standard agricultural feed transport (not included), into the hopper through an automated gate valve on the hopper lid. The horizontal motion of the linear drive operating the gate valve is converted into a vertical sealing force by an innovative leaf spring system, ensuring an airtight seal and reliable operation.

The custom ECU, using an open-source processor with an APL-designed circuit board, reads data from sensors installed in the hopper and opens the gate valve when the feedstock is low, then signals the motorized feed transport to reload the hopper. Once it detects the hopper is full, the ECU shuts off the feed transport then closes the gate valve. This smart automation also reads gate position and motor-current sensors to assure safe operation for both operators and the Power Pallet. If problems are detected, the ECU will set the Continuous Feed system into various safe and stable modes and trigger alarms to alert the operator.

Optional Accessory: Combined Heat and Power (CHP)

Our Combined Heat and Power (CHP) Accessory can be added to our Power Pallets, more than doubling their total system efficiency by adding the thermal output to the electrical output. APL’s CHP System uses a flat plate heat exchanger to capture heat from the engine’s cooling system in this stage 1 system to raise the temperature of the working fluid by as much as 14 °C.

This is possible because only 20% of the energy contained in the feedstock is able to be converted to electricity by our genset. Most of the other 80% is normally lost via heat in the engine’s cooling system and exhaust. By recovering some of this heat, the CHP allows the total efficiency of the whole system to exceed 35% by delivering up to 20 kW of thermal energy in addition to the 18 kW of electrical energy. This heat can be pumped via the working fluid to other locations where it can used for radiant floor heating and numerous other processes.

PREVIEW: UPCOMING PRODUCTS:

Quiet Clean Power: PC20 Power Cube

The Power Cube PC20 is a sensible solution to the critical global need for low-carbon energy, using agricultural and forestry waste materials to make on-demand renewable energy for a fraction of the cost of comparable diesel power. APL’s unique patented multi-stage gasification architecture, in combination with our innovative gasifier-engine thermal integration, our electronic control system and waste-heat recycling, gives the Power Cube unprecedented biomass fuel flexibility & efficiency; every 1.15 kg of biomass creates a kilowatt hour of power. More than just electricity, the PC20 also has the option of an integrated Combined Heat and Power (CHP) module, providing up to 30 kW of thermal energy for heating and drying, with no drop in power production. Quiet, compact and portable, the PC20 is easily transported to where the fuel is and where the power is needed. Its sleek stainless steel enclosure, sound insulation, emission controls and CE conformity allow for installation in almost any setting. Proudly made in California, the Power Cube PC20 is expected to be available in 2017.

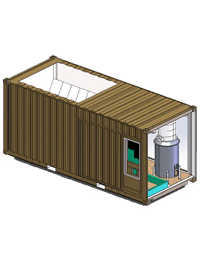

Powertainer PT150

The ALL Power Labs 150kW Powertainer is a compact and cost-optimized biomass power generation system, enclosed within a standard 20’ shipping container. The system is fully automated and complete: from biomass hopper, gasifier and gas filtering, to engine, generator and electrical output control – all within the shipping container envelope. The goal is a total-system-in-a box, drop it off the truck and go – no onsite construction required.

The Powertainer was originally developed as part of a US Dept of Energy project with the University of Minnesota, Morris, Cummins Power, and the Diesel Research Lab of U of Minnesota, Twin Cities. On January 23, 2015, All Power Labs received a $2M USD grant from the California Energy Commission to begin work on commercializing the Powertainer. Along with project partners UC Berkeley, Sierra Pacific Industries, and the Placer County Air Pollution Control District, APL will be working to make a modular power plant able to convert forest fire remediation waste into on demand clean energy. Pricing has yet to be determined but we expect deliveries by Q4 2017.