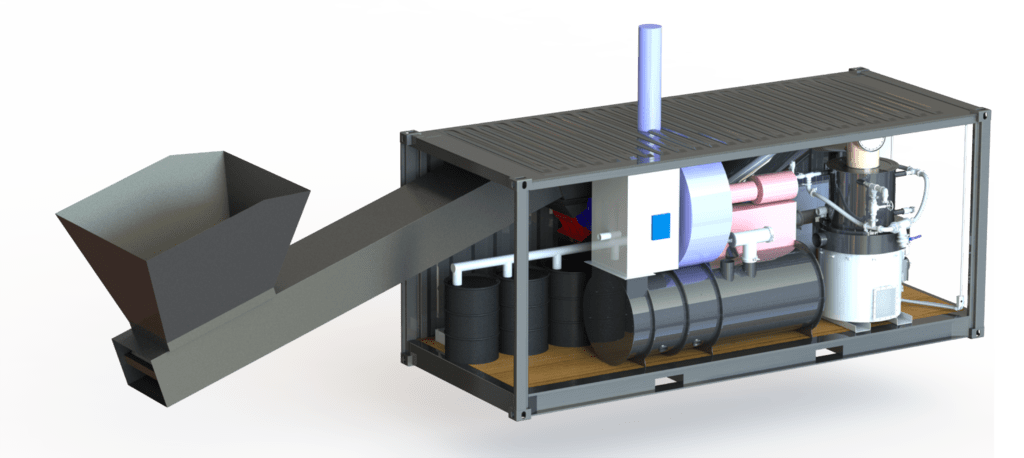

The ALL Power Labs CharTainer is a compact, high-volume, Combined Heat and Biochar (CHAB) pyrolyzer system enclosed within a standard 20-foot shipping container. The system is fully automated and complete – from biomass hopper, gasifier-retort, and clean-burning flare with heat exchangers to biochar takeoff – all integrated within the shipping container envelope. The CharTainer uses a scaled-up version of APL’s newest Swirl Hearth architecture previously refined and proven in our PT150 PowerTainer. The swirl hearth architecture includes technology innovation that widens the range of acceptable feedstock and ensures the quality of biochar produced.

The CharTainer is being developed to meet the ever-increasing demands for localized biomass waste disposal as well as high-quality, high-temperature, electrically active biochar in the agronomy and climate/carbon mitigation sectors. Partnering with our carbon-drawdown initiative, The Local Carbon Network, APL’s engineers have been working with biologists, agronomists, farmers, and climate researchers to perfect biochar-retort technology and biochar application techniques. One result of this work is the design of the Pilot CharTainer, capable of a 250 kgs-of-biomass-per-hour throughput delivering up to 50 kilograms per hour of SkyCarbon biochar, some of the highest quality, tar-free, geo-conducting biochar available.

We are currently developing a pilot unit with CEC funding. Our intent was to already be shipping commercial production units, but pandemic restrictions have pushed back the timeline. Our beta unit should be shipped to our first customer for testing in a real-world site soon. We offer these data with reasonable confidence given our long-running data acquisition in the development of our gasifier-genset systems and distribution of their biochar byproduct.

If you are interested in being considered for one of our first release versions of the Chartainer, please visit this fill out this Chartainer Priority Form to help us best match our limited production with the most qualified candidates.

Please review this Pilot CharTainer Spec sheet.

Please review this Appropriate Feedstock link. We are developing novel reactor architecture that will widen the feedstock range such as finer fuels. Testing will be ongoing in 2022 and we will update the table as results are completed.

The quality of the biochar produced is highly conductive with low tar/PAH content. Please review this Skycarbon Specification which show biochar qualities and certifications for walnut feedstock. We expect that the general qualities to be similar for other feedstock.

The CharTainer is a Combined Heat and Biochar unit (CHAB) with 20% biomass-to-biochar conversion rate. It does not have any electrical power output. The PowerTainer is a Combined Heat, Power and Biochar unit with 5% biomass-to-biochar conversion rate.

The CharTainer is being designed to process biomass waste streams on-site to minimize the waste disposal logistics and costs. The resulting biochar produced is a value-added product that can be used as a key ingredient in soil products. Examples of industries include – tree service companies, green waste recycling yards, nutshell producers, etc.

The Chartainer is being developed with the generous support of the California Energy Commision who are committed to the development of a 100% renewable energy future for California.